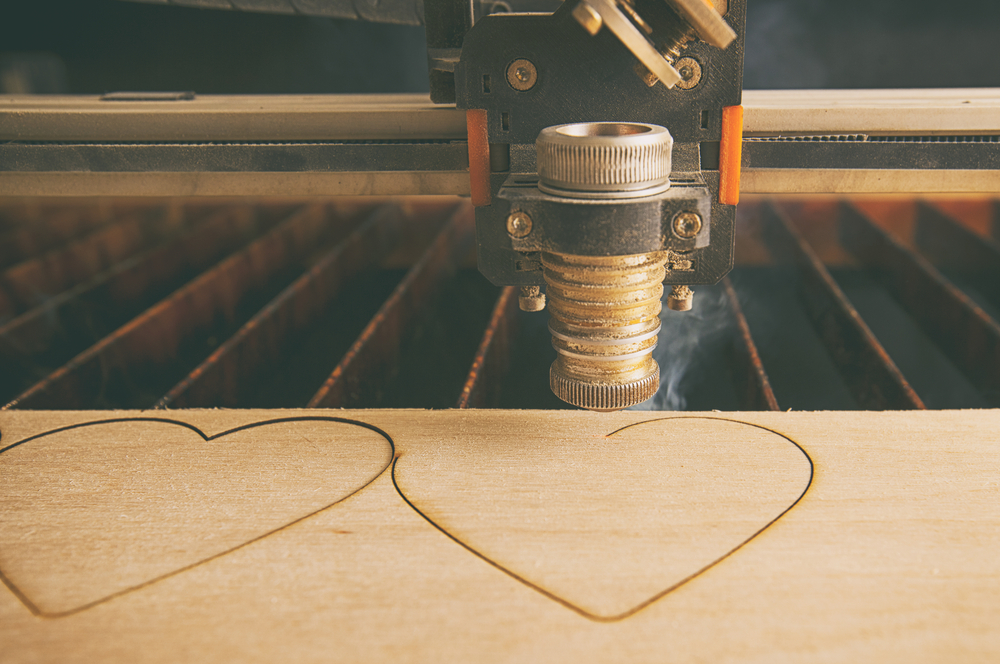

Maintaining a home laser die cutter is essential to ensure its longevity and optimal performance. With the right care and attention, you can extend the lifespan of your machine and continue creating intricate designs with ease. In this article, we will explore some helpful tips and tricks that will keep your home laser die cutter running smoothly for years to come. From regular cleaning and lubrication to proper storage and maintenance, these simple yet effective strategies will help you make the most out of your investment. So, let’s dive in and discover how you can keep your home laser die cutter in top-notch condition!

Tips for Maintaining and Extending the Lifespan of a Home Laser Die Cutter

Welcome to this comprehensive article where we will discuss various tips and techniques to help you maintain and extend the lifespan of your home laser die cutter. By following these guidelines, you can ensure optimal performance and longevity for your machine, allowing you to continue creating beautiful projects for years to come.

Perform Regular Cleaning

One of the most important aspects of maintaining a home laser die cutter is regular cleaning. As you use your machine, dust, debris, and residue can accumulate on various components, affecting the overall performance and cutting quality. To prevent this, it is crucial to establish a routine cleaning schedule.

Start by disconnecting the power supply and then remove the cutting bed and other removable parts. Use a soft brush or cloth to gently remove any loose debris from the surfaces. Be cautious not to scratch or damage any delicate components. For tougher residue, you can use a mild cleaning solution recommended by the manufacturer.

Check and Replace the Laser Tube

The laser tube is a critical component of a laser die cutter that provides the necessary power for cutting and engraving. Over time, the laser tube can degrade, resulting in reduced performance and accuracy. Therefore, it is essential to periodically check the condition of the laser tube and replace it if necessary.

Inspect the laser tube for signs of damage, such as discoloration or cracks. Additionally, pay attention to any loss of power or fluctuations in cutting quality, as these can also indicate a failing laser tube. If you notice any of these issues, contact the manufacturer or a professional technician to have the tube replaced.

Ensure Adequate Ventilation

Proper ventilation is essential for the safe operation and longevity of a home laser die cutter. During the cutting process, the machine generates fumes and smoke that need to be effectively removed to protect both the operator and the components of the machine.

Ensure that your machine is placed in a well-ventilated area or, ideally, install a dedicated ventilation system. This will not only improve the lifespan of your laser die cutter but also maintain a cleaner working environment.

Keep Moving Parts Lubricated

To ensure smooth and accurate movement, it is necessary to keep the moving parts of your laser die cutter properly lubricated. This includes components such as the belts, guide rails, and bearings. Regular lubrication will help reduce friction and wear, ultimately extending the lifespan of these parts.

Refer to the user manual or contact the manufacturer for the recommended lubricant and frequency of application. Remember to wipe off any excess lubricant to prevent attracting dust and debris.

Monitor and Adjust Laser Focus

Maintaining the correct laser focus is crucial for achieving precise and consistent cuts. Over time, the focal point of the laser beam can shift due to vibrations or other factors, leading to reduced cutting quality.

Regularly check and adjust the laser focus to ensure optimal performance. Follow the manufacturer’s instructions on how to perform this task safely and accurately. Calibration tests or alignment tools may be provided to assist you in this process.

Avoid Overworking the Machine

While it can be tempting to push your laser die cutter to its limits, overworking the machine can lead to premature wear and damage. Each machine has its limitations in terms of cutting speed, power, and duty cycle.

Avoid running the machine continuously for extended periods without giving it sufficient breaks. Make sure to follow the manufacturer’s recommendations regarding usage and resting intervals. By respecting these guidelines, you can avoid excessive strain on the machine and extend its overall lifespan.

Use the Recommended Materials

Using the appropriate materials for your laser die cutter is crucial for its longevity. Different machines have different compatibility and power requirements. Using unsuitable materials can damage the machine, degrade cutting quality, and even pose safety hazards.

Read the user manual thoroughly to understand the compatibility of materials with your machine. If you are unsure about whether a specific material is suitable, consult the manufacturer or seek professional advice.

Check and Replace Consumables

Regularly inspecting and replacing consumable parts is essential for maintaining the optimal performance of your laser die cutter. Consumables include items such as lenses, mirrors, and focus tools. These parts can become dirty or worn over time, affecting the quality of the laser beam and the accuracy of cuts.

Inspect the consumables on a regular basis and clean or replace them as necessary. Follow the manufacturer’s guidelines for care and replacement intervals. By keeping the consumables in good condition, you can ensure consistent and high-quality results.

Keep Software and Firmware Updated

To optimize the performance of your laser die cutter, it is crucial to keep the software and firmware up to date. Software updates often include improvements in cutting algorithms, speed, and overall functionality. Firmware updates, on the other hand, can address any hardware-related issues and ensure compatibility with the latest software versions.

Regularly check the manufacturer’s website or contact their customer support for any available updates. Following the instructions provided, carefully update the software and firmware of your machine to benefit from the latest enhancements.

Schedule Professional Servicing

Lastly, but just as important, consider scheduling professional servicing for your home laser die cutter. While regular cleaning and maintenance done by yourself are essential, there are technical aspects that require the expertise of a trained technician.

By engaging a professional, you can ensure a thorough inspection and servicing of your machine. They can check and adjust critical components, diagnose potential issues, and perform any necessary repairs. Professional servicing at recommended intervals will help keep your laser die cutter in optimal condition for an extended lifespan.

By following these tips for maintaining and extending the lifespan of your home laser die cutter, you can enjoy years of reliable performance and exceptional cutting quality. Remember to perform regular cleaning, check and replace the laser tube when needed, ensure adequate ventilation, keep moving parts lubricated, monitor and adjust laser focus, avoid overworking the machine, use recommended materials, check and replace consumables, keep software and firmware updated, and schedule professional servicing. By taking good care of your laser die cutter, you can continue creating amazing projects and unleash your creativity without any compromise.