Have you ever wondered how you can enhance your laser cutting projects to achieve more precise and professional results? Whether you’re a hobbyist or a professional, understanding how to accessorize your laser cutter can transform the way you work. With the right tools in your arsenal, what was once challenging can become significantly clearer and more efficient. From air assist systems to focusing tools and effective ventilation, these accessories are more than just add-ons—they’re essentials that could elevate your creative and functional projects. So, let’s explore how these accessories can take your laser cutting to the next level.

Understanding Laser Cutter Components

To understand why certain accessories make a significant impact, it’s beneficial to familiarize yourself with the primary components of a laser cutter. Here’s a simple table to help you understand the basic parts:

| Component | Function |

|---|---|

| Laser Tube | Generates the laser beam used for cutting or engraving. |

| Laser Head | Directs the laser beam onto the material. |

| Laser Bed | Surface where the material is placed for cutting or engraving. |

| Control Panel | Allows the user to operate and control the machine. |

| Exhaust System | Removes fumes and particles from the cutting area. |

Each part plays a crucial role in ensuring the laser cutter operates efficiently and effectively. The performance and longevity of your laser cutter heavily depend on maintaining and upgrading these components when necessary.

Essential Laser Cutter Accessories

With a basic understanding of laser cutting, let’s explore some indispensable accessories that can make a substantial difference in your cutting experience.

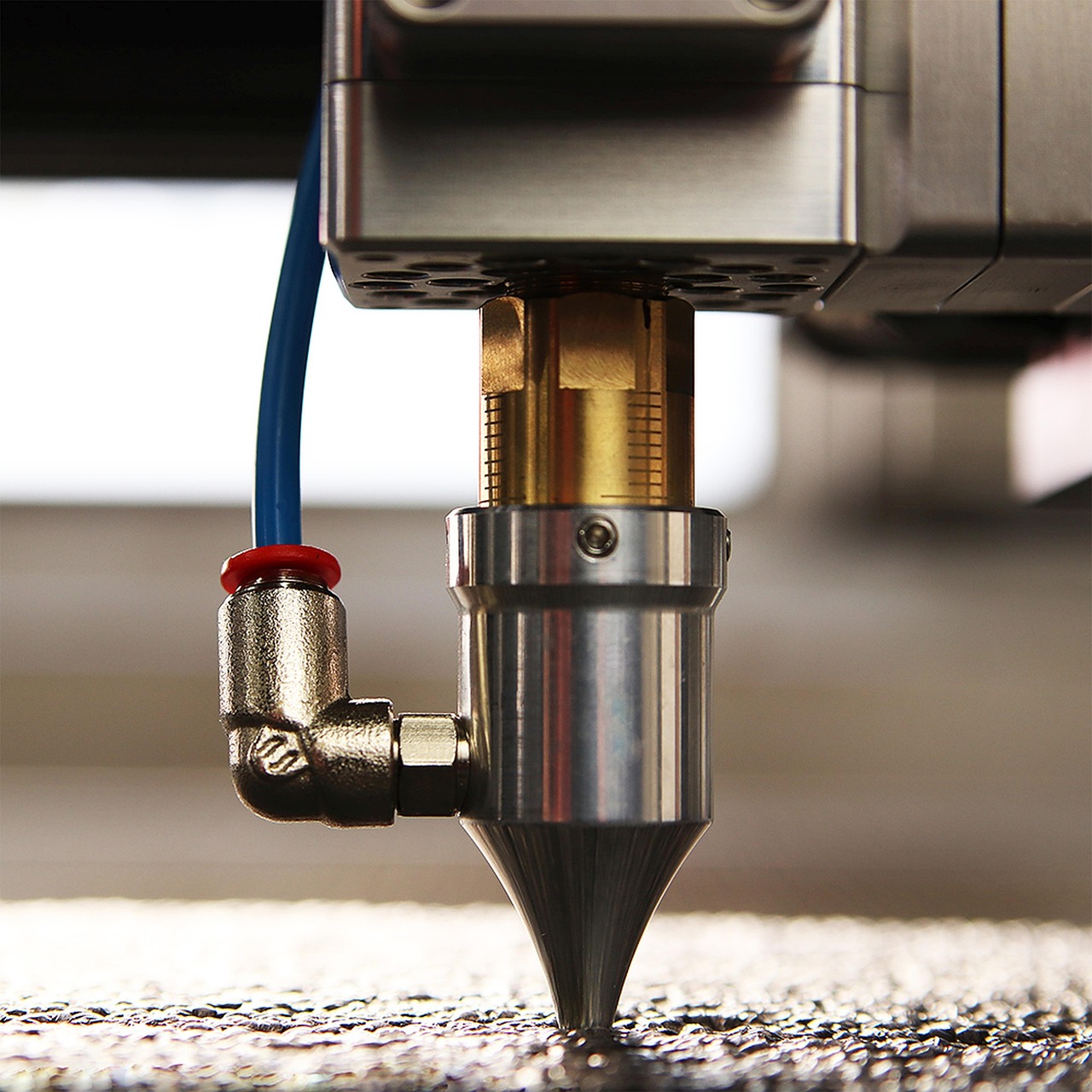

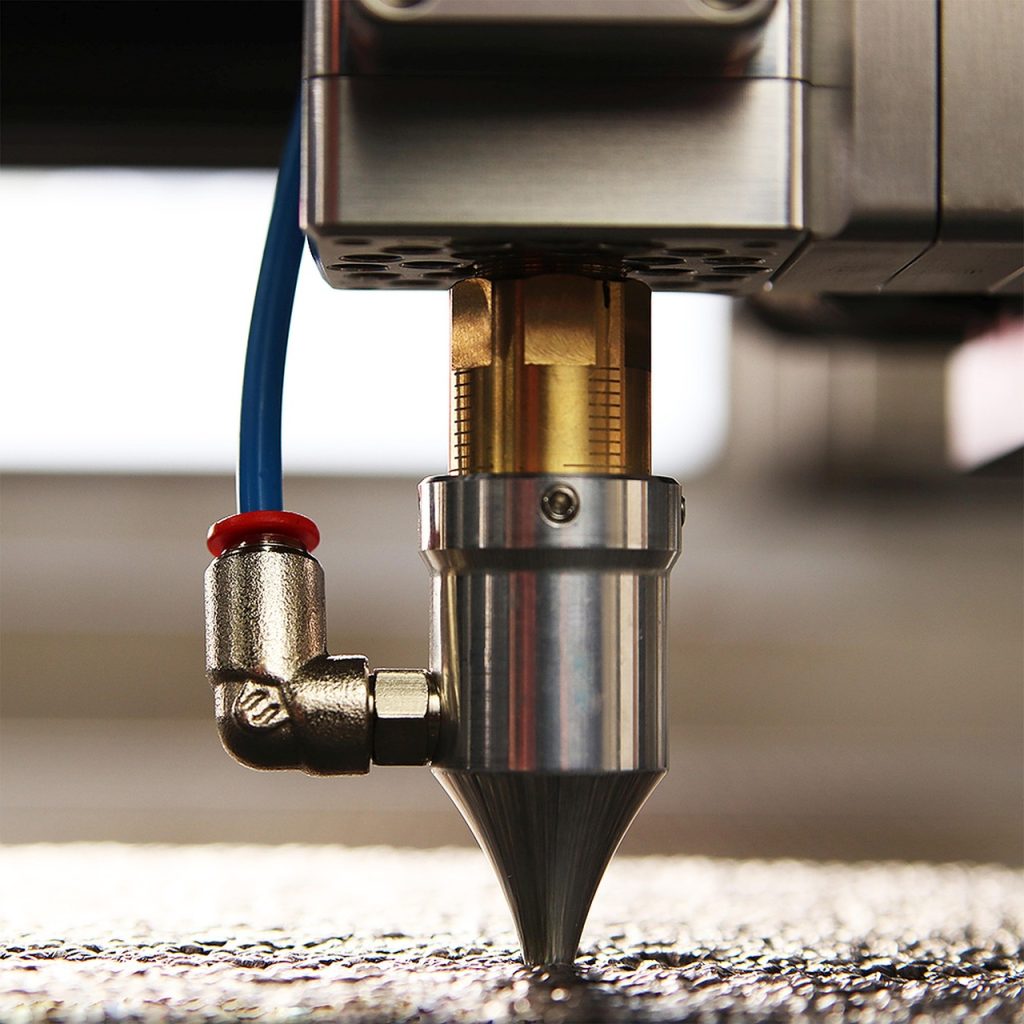

Air Assist Kits

Air assist is more than just a fancy add-on; it’s a transformative tool that can result in cleaner cuts and engravings. Here’s why:

- Cleaner Cuts: The air assist system blows a constant stream of air across your material’s surface as the laser cuts. This air helps to blow away debris and prevents it from settling back onto the material, leading to cleaner and more precise cuts.

- Reduced Heat: The stream of air also helps to cool the material and the laser cut zone, significantly reducing the chances of fire hazards and material distortion.

- Extended Laser Life: By minimizing heat buildup, an air assist can prolong the life of your laser head and other components, ultimately leading to cost savings.

An air assist kit typically includes a compressor and a series of tubes that direct a steady stream of air onto the cutting path. It’s a small upgrade that brings substantial enhancements, particularly if you cut materials like wood or acrylic that are prone to flaming or charring.

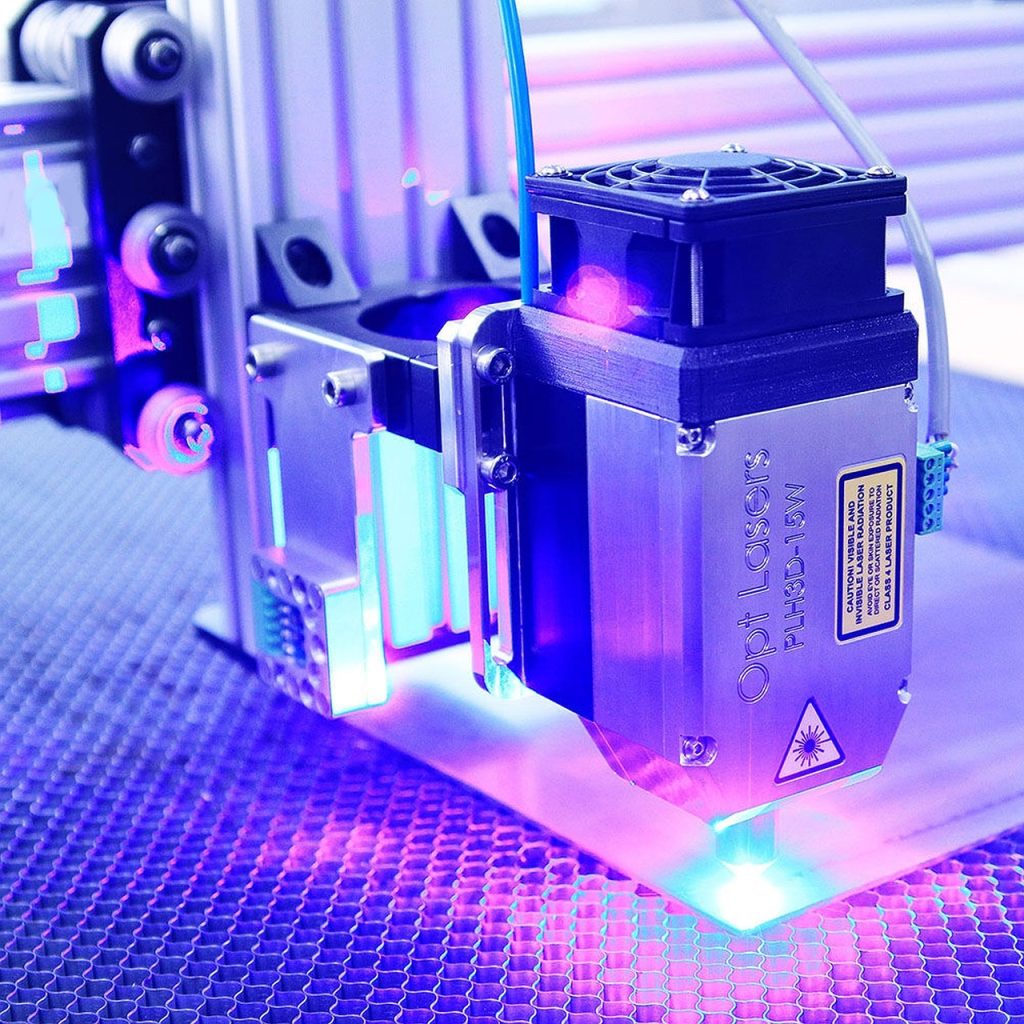

Focusing Tools

Precision is paramount in laser cutting—this is where focusing tools come into play. Ensuring your laser is properly focused can make the difference between a perfect cut and a lackluster one. Focusing tools help you:

- Achieve Sharp Details: A well-focused laser beam allows you to capture fine details without blur or shadow.

- Optimize Cutting Speed: With proper focus, the laser can cut through materials more quickly and efficiently.

- Minimize Material Waste: Precise cuts mean less wasted material, resulting in cost efficiencies over time.

Focusing is typically done with a focusing lens tool or a manual method involving calibrating the distance between the laser head and the material. Whichever method you choose, this step is crucial for achieving professional-quality results.

Ventilation Systems

A well-functioning ventilation system is essential for both safety and comfort during your laser cutting processes. Let’s explore what it brings to the table:

- Fume Extraction: Cutting and engraving on materials like acrylic or MDF release fumes that can be harmful if inhaled. An effective ventilation system ensures these are efficiently extracted.

- Particle Control: It also removes any microscopic dust particles produced during the process, keeping your workspace clean.

- Increased Machine Performance: By keeping the environment around the laser cleaner, ventilation systems help in maintaining the laser’s performance over extended periods.

Installing a robust ventilation system not only safeguards your health but also enhances your laser cutter’s production environment, allowing longer sessions with improved safety.

Choosing the Right Accessories

Adding accessories to your laser cutter can provide numerous benefits, yet selecting the right ones can feel overwhelming given the many options available. Consider these factors when making your decision:

Determining Your Needs

Ask yourself a few key questions:

- What materials am I cutting most frequently? Accessories may vary in importance based on whether you cut woods, metals, plastics, etc.

- What’s my primary focus: speed or precision? This will impact whether you prioritize accessories that enhance cut quality or those optimizing workflow efficiency.

- What’s my budget? Assess how much you’re willing to invest immediately versus over time, as some accessories might require a significant upfront investment.

Compatibility

Ensure any accessory you purchase is compatible with your specific laser cutter model. Not all accessories are universally fit, so it’s vital to check the specifications before buying.

Brand and Quality

When it comes to tools and accessories, investing in quality ensures longevity and performance. Opt for well-reviewed brands that provide customer support and available spare parts when needed.

Setting Up and Maintaining Accessories

Once you’ve acquired your accessories, setting them up properly and maintaining them becomes essential for getting the most out of your investment.

Installation Tips

- Follow Manuals: Always stick closely to the installation manuals provided by the accessory manufacturers.

- Calibration: After the installation, don’t forget to calibrate your accessories, such as adjusting the air pressure in an air assist system.

- Test Runs: Conduct test cuts or runs with scrap materials to ensure everything is functioning as expected before treading on your actual projects.

Maintenance Practices

- Routine Checks: Periodically check your accessories for wear or malfunction to avoid unexpected downtimes.

- Cleanliness: Keep lenses and other optical parts clean to prevent dust accumulation and improve results.

- Software Updates: Ensure any related software is up to date to capitalize on the latest improvements and security updates.

Expanding Your Creative Horizons

Now that you have an understanding of essential laser cutter accessories, you might be wondering how to apply these in practical projects. Here’s how they can broaden your creative scope:

Enhancing Artistic Projects

From engraving detailed patterns on wood to intricate etchings on acrylic, the right focus and clean cuts brought by these accessories can drastically improve the aesthetics of your projects.

Improving Prototyping Efficiency

For business or tech-savvy individuals engaged in rapid prototyping, precision and speed are key. Accessories like focusing tools can help you stretch your productivity by delivering high-quality components swiftly.

Facilitating Education and Learning

In educational settings, safety and user-friendliness are critical. Accessories that improve safety, such as good ventilation systems, contribute to a more conducive learning environment while ensuring the safety of students and staff.

Troubleshooting Common Issues

Even with the best accessories, you might encounter issues that require troubleshooting. Here are some common scenarios and potential solutions:

Overheating and Flame Issues

- Check Air Assist: Ensure that your air assist is functioning, as it plays a crucial role in reducing overheating and flammable occurrences.

- Reduce Laser Power: Sometimes, using too much power can lead to material burning rather than cutting.

Poor Cut Quality

- Re-focus Laser: Ensure that the laser is appropriately focused using the focusing tools available to you.

- Inspect Machine Leveling: Verify that your laser cutter is on a flat, stable surface, as any tilting can affect cut quality.

Inefficient Ventilation

- Clear Filters: Make sure that your ventilation filters are clean and not obstructed, as these should allow for free flow of air and fume extraction.

- Inspect Ducts: Over time, ducts can become clogged. Regular checks and cleaning allow for better airflow and efficiency.

Staying Ahead in the Laser Cutting World

New technologies and techniques are emerging in the realm of laser cutting that can further enhance your projects. Staying up-to-date through workshops, seminars, and online communities can introduce you to other groundbreaking methods and newer accessories that could transform your work even more.

Connecting with Communities

Being part of communities can provide you with practical tips, inspiration, and support from fellow laser cutting enthusiasts. These communities can be immensely valuable when you need advice on exploring new accessories and techniques.

Attending Workshops

Workshops are a great place to see accessories in action and understand how they might fit into your workflow. These hands-on experiences are invaluable for testing the latest developments in laser cutting accessories.

Conclusion

Investing in the right laser cutting accessories can be a game-changer, pushing the boundaries of what you can achieve with this powerful tool. Whether seeking sharper cuts, faster throughput, or simply trying to work in a safer environment, each accessory plays a significant part in achieving those goals. By opting for quality and compatibility, ensuring proper installation, and maintaining those tools, you aren’t just upgrading your laser cutter – you’re upgrading your entire creative process. So delve into this world of possibilities, and let your projects soar to new heights!