Have you ever wondered if you could have a laser die cutter right in your own home? Well, the answer is yes, and it’s easier than you might think! With a home laser die cutter, you can create intricate designs and cut a variety of materials with precision. But how exactly does it work? In this article, we’re going to take a closer look at the world of laser die cutting and give you a beginner’s guide to getting started.

First off, let’s talk about the setup process. Setting up a home laser die cutter is actually quite simple. Most machines come with detailed instructions and guides that will walk you through the process step by step. You’ll need to make sure you have a designated workspace with proper ventilation and safety precautions in place. Once your machine is set up, you’ll need to connect it to a computer or design software to start creating your projects.

Now, let’s dive into how to use a laser die cutter. The beauty of these machines is that they are incredibly versatile. You can cut a wide range of materials, including paper, cardboard, fabric, wood, and even some plastics. To start, you’ll need to import or create a design on your computer and send it to the machine. The laser will then follow the design and cut or engrave the material accordingly. It’s important to adjust settings such as cutting depth and speed depending on the material you’re working with.

In this article, we’ve only scratched the surface of what you can do with a laser die cutter at home. From creating custom invitations and cards to designing intricate jewelry or home decor, the possibilities are truly endless. Stay tuned for more detailed guides and tips on how to get the most out of your home laser die cutter. Get ready to unleash your creativity and bring your ideas to life!

A Beginner’s Guide to Using a Laser Die Cutter at Home

What is a Laser Die Cutter?

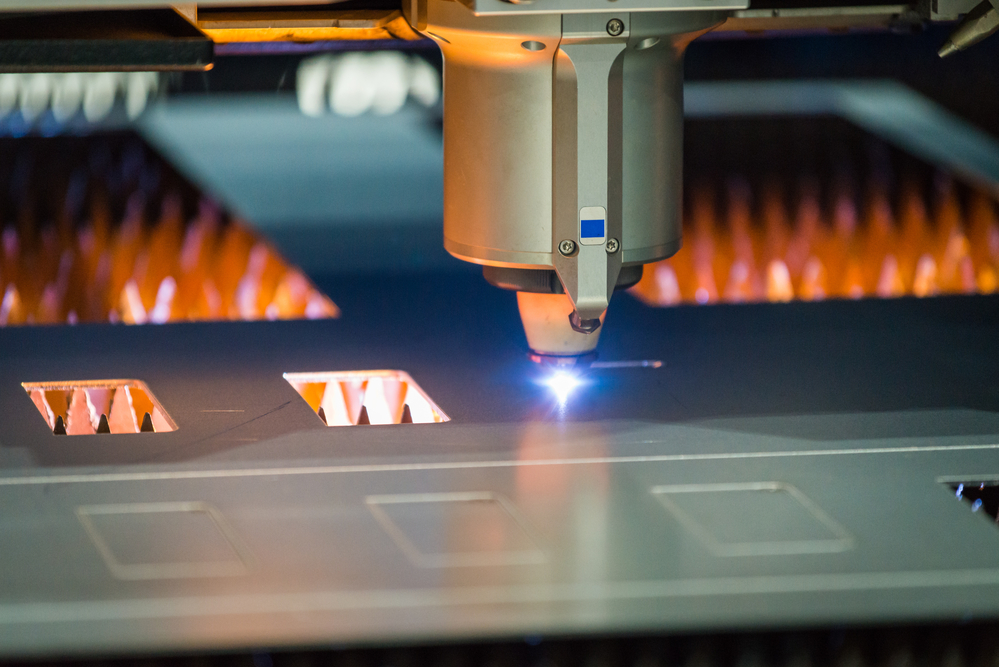

Before we dive into the process of setting up and using a laser die cutter at home, let’s first understand what it is. A laser die cutter is a machine that uses a high-powered laser beam to cut precise and intricate shapes into various materials such as paper, wood, or fabric. Unlike traditional die cutting machines that rely on physical dies, a laser die cutter creates designs digitally, allowing for more flexibility and creativity in your projects.

Definition and Function of a Laser Die Cutter

A laser die cutter works by directing a laser beam through a series of mirrors and lenses. The laser is controlled by computer software, which allows you to create and edit designs to be cut. The laser beam melts or vaporizes the material it comes into contact with, resulting in clean and precise cuts. The level of precision that a laser die cutter offers is unparalleled, making it a popular choice for hobbyists, crafters, and small businesses.

Different Types of Laser Die Cutters

There are various types of laser die cutters available in the market, each with its own set of features and capabilities. Here are some common types:

- CO2 Laser: These are the most common type of laser die cutters, utilizing a carbon dioxide gas laser to cut through materials. They are versatile and can cut a wide range of materials with precision.

- Fiber Laser: Fiber laser cutters are specifically designed for cutting metal materials. They use a solid-state laser and are more powerful than CO2 lasers when it comes to cutting metals.

- UV Laser: UV lasers are used for highly precise and intricate cutting and engraving. They are commonly used in the electronics industry for micromachining and circuit board production.

Advantages of Using a Laser Die Cutter

Using a laser die cutter at home offers several advantages. Here are some key benefits:

- Precision: Laser die cutters are known for their accuracy and precision. They can cut intricate designs, even on delicate materials, with negligible margins of error.

- Versatility: Laser die cutters can work with a wide range of materials, including paper, wood, fabric, acrylic, and more. This versatility allows you to explore various crafting projects and applications.

- Time Efficiency: Laser cutting is a quick and efficient process compared to manual cutting methods. It can handle complex designs and multiple cuts in a fraction of the time.

- Customization: With a laser die cutter, you have the freedom to create personalized designs and patterns. This opens up endless possibilities for DIY projects and creative endeavors.

- Replication: Once you have a design file, you can easily replicate it multiple times with consistent results. This is especially useful for small businesses or individuals looking to create products in bulk.

Choosing the Right Laser Die Cutter for Home Use

Now that you understand the basics of a laser die cutter, let’s explore how to choose the right one for your home setup.

Considerations for Home Use

Before making a purchase, consider the following factors:

- Space: Assess the available space in your home for the laser die cutter. Laser cutters come in various sizes, so make sure to choose one that fits comfortably in your work area.

Budget and Space Requirements

The price range for laser die cutters can vary significantly depending on the brand, model, and features. Set a budget and research models that fall within your price range. Additionally, consider the ongoing costs of consumable parts, such as laser tubes and lenses.

Features to Look for in a Home Laser Die Cutter

When selecting a laser die cutter for home use, keep these features in mind:

- Power and Speed: Consider the power output and cutting speed of the machine. Higher power lasers can cut through thicker materials, while faster cutting speeds save time.

- Cutting Bed Size: Check the size of the cutting bed to ensure it is suitable for the materials you plan to work with.

- Software Compatibility: Ensure that the laser die cutter is compatible with design software you are comfortable using.

- Safety Features: Look for safety features such as a laser enclosure, emergency stop button, and interlock switches.

Popular Brands and Models

There are several reputable brands that offer laser die cutters for home use. Some popular options include:

- Epilog Laser

- Glowforge

- Boss Laser

Setting Up Your Laser Die Cutter at Home

Once you have chosen the right laser die cutter for your home, it’s time to set it up and get started on your creative journey.

Unboxing and Assembling the Laser Die Cutter

Follow the manufacturer’s instructions carefully to unbox and assemble the laser die cutter. This usually involves attaching the laser head, connecting cables, and ensuring all components are securely in place.

Connecting to Power and Safety Precautions

Before connecting to power, make sure to read and understand the safety guidelines provided by the manufacturer. Laser cutters use high-powered lasers, so it’s crucial to follow safety protocols to protect yourself and your surroundings.

Adjusting Laser Power and Speed Settings

Each material requires different laser power and speed settings for optimal cutting results. Refer to the manufacturer’s guidelines or experiment with test cuts to determine the ideal settings for your specific material.

Calibrating the Laser Die Cutter

Calibration ensures that the laser beam is accurately aligned with the cutting bed. Follow the calibration instructions provided by the manufacturer to ensure precise and consistent cutting.

Preparing Materials for Laser Cutting

Before you start cutting, it’s essential to properly prepare your materials.

Selecting Suitable Materials

Laser die cutters can work with a variety of materials, but not all materials are suitable. Consult the manufacturer’s recommendations or conduct your own research to determine which materials are safe and suitable for laser cutting.

Preparing the Materials for Cutting

Prepare your materials by ensuring they are free from dust, debris, or any obstructions that could interfere with the cutting process. Trim or flatten materials if necessary to ensure they lie flat on the cutting bed.

Securing the Material on the Cutting Bed

Use masking tape or other suitable methods to secure your material firmly onto the cutting bed. This prevents movement during the cutting process and ensures accurate cuts.

Importing and Preparing Design Files

Design files can be created using various software programs such as Adobe Illustrator or CorelDRAW. Import your design files into the laser cutter’s software and make any necessary adjustments or modifications before cutting.

Operating the Laser Die Cutter

Once your materials are prepared, it’s time to operate the laser die cutter.

Understanding the Control Panel and Software Interface

Take the time to familiarize yourself with the control panel and software interface of your laser die cutter. This will allow you to navigate through the settings, adjust parameters, and execute your cutting jobs efficiently.

Executing Test Cuts and Adjustments

Before running a full cutting job on your actual material, it’s advisable to perform test cuts on a scrap or similar material. This allows you to make any necessary adjustments to the power and speed settings.

Running a Full Cutting Job

Once you are satisfied with the results of your test cuts, proceed to run a full cutting job on your desired material. Make sure to monitor the process closely to ensure everything goes smoothly.

Monitoring the Cutting Process

During the cutting process, keep a close eye on the laser cutter. Avoid leaving it unattended, especially if you are cutting flammable materials. Be prepared to pause or stop the process if any issues arise.

Maintenance and Safety Tips

To ensure the longevity of your laser die cutter and maintain a safe working environment, follow these maintenance and safety tips:

Cleaning and Maintaining the Laser Die Cutter

Regularly clean the lens to remove any dust or debris that may affect the quality of your cuts. Refer to the manufacturer’s instructions for specific cleaning guidelines. Additionally, lubricate moving parts and check for any signs of wear or damage.

Replacing Consumable Parts

Laser tubes and lenses are consumable parts that may need to be replaced over time. Keep spare parts on hand and follow the manufacturer’s guidelines for replacement intervals.

Following Safety Protocols

Always wear the appropriate personal protective equipment (PPE) when operating the laser die cutter, including safety glasses and gloves. Ensure proper ventilation in your workspace to minimize exposure to fumes or smoke.

Proper Ventilation and Fire Safety

Install proper ventilation to remove fumes and smoke generated during the cutting process. In addition, have fire safety measures in place, such as a fire extinguisher, in case of emergencies.

Expanding Your Laser Cutting Skills

Once you have mastered the basics of using a laser die cutter, you can start exploring advanced techniques and applications.

Learning Advanced Techniques and Applications

Take advantage of online resources, tutorials, and forums to learn advanced techniques for laser cutting. Experiment with different settings and explore the capabilities of your laser die cutter.

Exploring Different Material Options

Don’t limit yourself to just one type of material. Laser die cutters can work with a wide range of materials, so branch out and experiment with various substances to unlock new creative possibilities.

Experimenting with Designs and Personalization

The beauty of laser cutting lies in its ability to create unique and personalized designs. Play with different designs, fonts, and patterns to add a personal touch to your projects.

Joining Laser Cutting Communities and Workshops

Immerse yourself in the laser cutting community by joining online forums or attending local workshops. Connect with fellow enthusiasts, share ideas, and gain inspiration from others in the field.

Conclusion

In conclusion, a laser die cutter is an incredibly versatile and precise tool that offers endless possibilities for creative projects. With the right machine, proper setup, and a little practice, you can bring your designs to life with ease. Whether you’re a hobbyist or a small business owner, a laser die cutter at home can empower you to take your craftsmanship to the next level. So, get ready to unleash your creativity and embark on an exciting laser cutting journey!

Benefits of Owning a Laser Die Cutter at Home

- Precision and accuracy in cutting

- Versatile and can work with various materials

- Time-efficient and capable of handling complex designs

- Allows for customization and replication of designs

Empowering DIY Projects and Creative Endeavors

- Laser die cutters provide the freedom to create personalized and unique designs

- Offers the potential for small businesses to create products in bulk

Summary of Key Points

- A laser die cutter uses a high-powered laser beam to cut precise and intricate shapes in various materials.

- Consider factors such as space, budget, and desired features when choosing a laser die cutter for home use.

- Properly prepare materials and adjust settings before running a cutting job.

- Follow maintenance and safety tips to ensure optimal performance and a safe working environment.

- Expand your laser cutting skills by learning advanced techniques, exploring different materials, and joining the laser cutting community.